API 11AX Ball and Seat for Subsurface Rod Pump

Short Description:

* API certified manufacturer

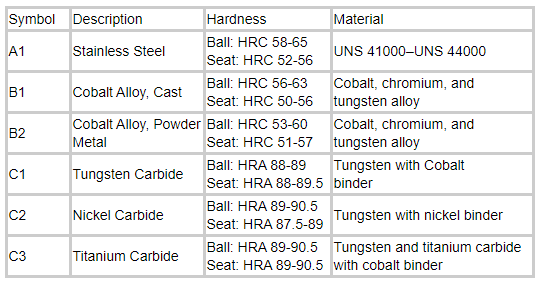

* Tungsten Carbide, Nickel/Cobalt/Titanium Binder

* Sinter-HIP Furnaces

* Sintered, finished standard, and mirror lapping ;

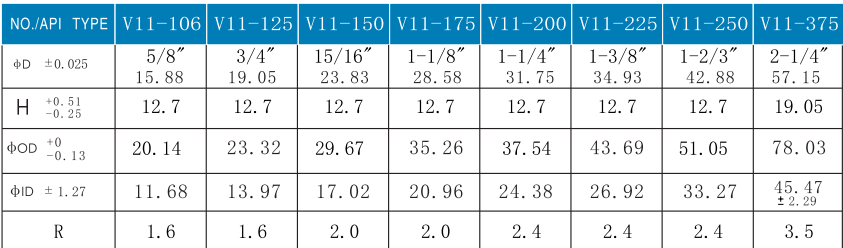

* Additional sizes,tolerances, grades and quantities are available upon request.

Pump valves are made of balls and seats and they are a key component when working under high hydraulic pressure due to depth. Only a perfect design and a correct selection of the material can guarantee their service life.

Valve balls and valve seats are widely used in oil fields , their performance directly affects the use effect and service life of the pumps. Each ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact.

Tungsten carbide ball & seat, made from virgin raw materials, have high hardness, wear-resistance, corrosion resistance, and resistance to bending. We are able to supply Carbide Balls in various desired material specifications including TC Cobalt, TC Nickel and TC Titanium, and the TC Balls are manufactured as per ISO and Anti-Friction Bearing Manufacturer Association (AFMBA) standards.

The tungsten carbide valve ball and seat will be used widely to the stationary and roving unidirectional valve in various tube-type oil suction pump due to their high hardness, wear and corrosion resistance as well as good anti-compression and thermal shock characters with a high pumping effect and a long pump check cycle for raising of sand, gas and wax containing thick oil from wells.

Blank balls and finished balls can be both supplied. Standard and non-standard balls are available.

We offer you valve ball and seat pre-sale services, after-sale services which including sales guidance, information supply & technical support, technical drawing supply, production planning provide, production schedule provide, inspection support and certificate provide.

Guanghan ND Carbide produces a wide variety of wear-resistant and corrosion-resistant tungsten carbide

components.

*Mechanical seal rings

*Bushings, Sleeves

*Tungsten Carbide Nozzles

*API Ball and Seat

*Choke Stem,Seat, Cages, Disk, Flow Trim..

*Tungsten Carbide Burs/ Rods/Plates/Strips

*Other custom tungsten carbide wear parts

------------------------------------------------------------------------------------------------------------------------------------------

We offer a full range of carbide grades in both cobalt and nickel binders.

We handle all processes in house following our customers' drawings and material specification. Even if you don't see

it list here, if you have the ideas we will produce.

Q: Are you trading company or manufacturer ?

A: We are manufacturer of tungsten carbide since 2004. We can supply 20 tons tungsten carbide product per

month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generallyit will take 7 to 25 days after order confirm.The specific delivery time depends on the specific product

and the quantity you needed.

Q: Do you provide samples? is it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers' cost.

Q: Do you test all your goods before delivery?

A: Yes, we will do 100% test and inspection on our cemented carbide products before delivery.

1. FACTORY PRICE;

2.Focus carbide products manufacturing for 17 years;

3.lSO and AP| certified manufacturer;

4.Customized service;

5. Fine quality and fast delivery;

6. HlP furnace sintering;

7. CNC machining;

8.Supplier of Fortune 500 company.