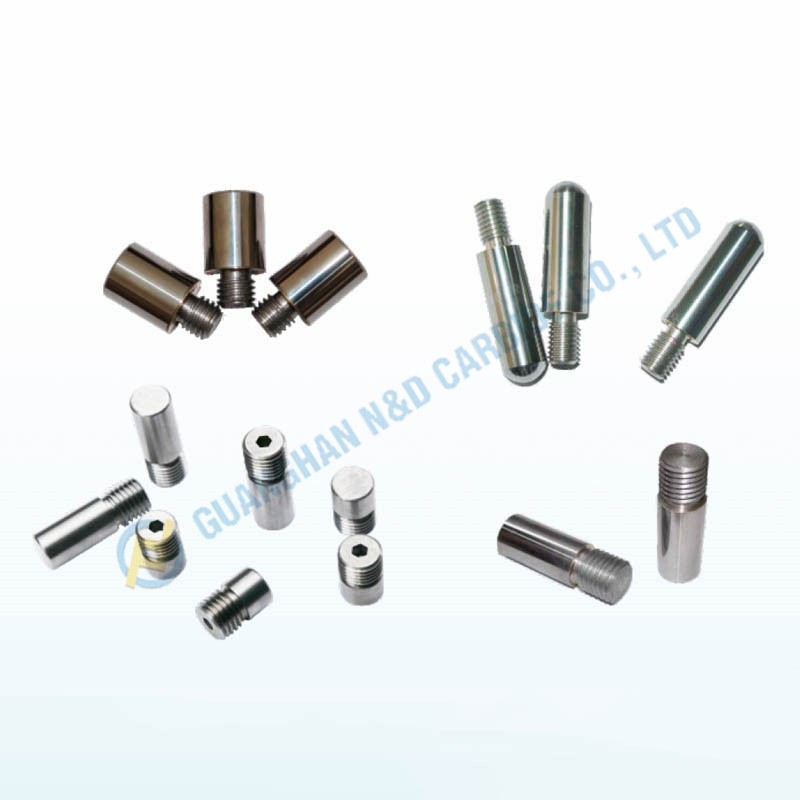

Tungsten Carbide Pins

Short Description:

* Tungsten Carbide, Nickel/Cobalt Binder

* Sinter-HIP Furnaces

* CNC Machining

* Sintered, finished standard

* Additional sizes,tolerances, grades and quantities are available upon request.

Tungsten carbide can be pressed and formed into customized shapes, can be grinded with precision, and can be welded with or grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended, including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc. Tungsten carbide is widely used in industrial machinery, wear resistant tools and anti-corrosion.

The quality of the rotor significantly influences the performance and durability of a bead mill. Selecting the right pins for rotors is therefore decisive for the product quality and your system production costs. Tungsten carbide pins/pegs is famous for the high hardness and high density, you can benefit the 10times wear-resistance and durability performance than the normal steels.

1. Ideal choice for Nanogrinding bead mill

2. The pegs /counter pegs of rotor is efficient activation of grinding beads

3. Cost Saving –The service life of Miller pegs have been proven no less than 4000hrs

4. Maximum energy efficiency- due to smaller beads and highest power density

Tungsten carbide pins have a good wear resistance, it’s suitable to handle from low to high viscous products, and improve the effect of distributions and millings.