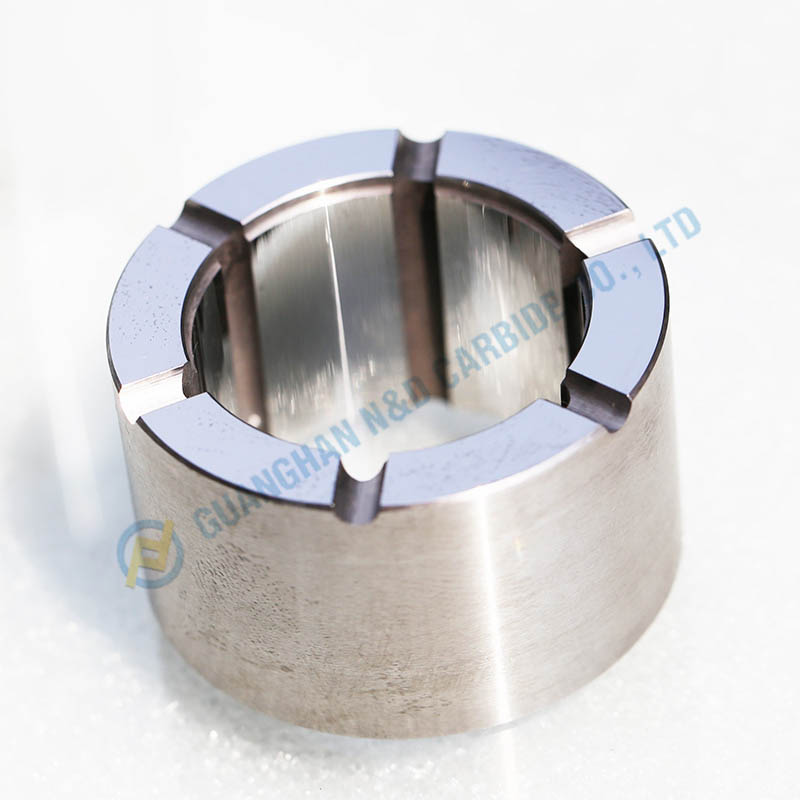

China Wholesale Oem Odm Custom Tungsten Carbide Bearing Sleeve Made In China Factories – Custom Carbide Bush and Sleeve – N&D

Short Description:

China Wholesale Oem Odm Custom Tungsten Carbide Bearing Sleeve Made In China Factories – Custom Carbide Bush and Sleeve – N&D Detail:

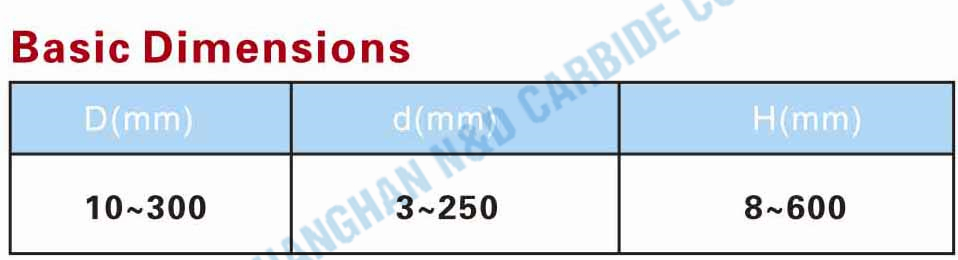

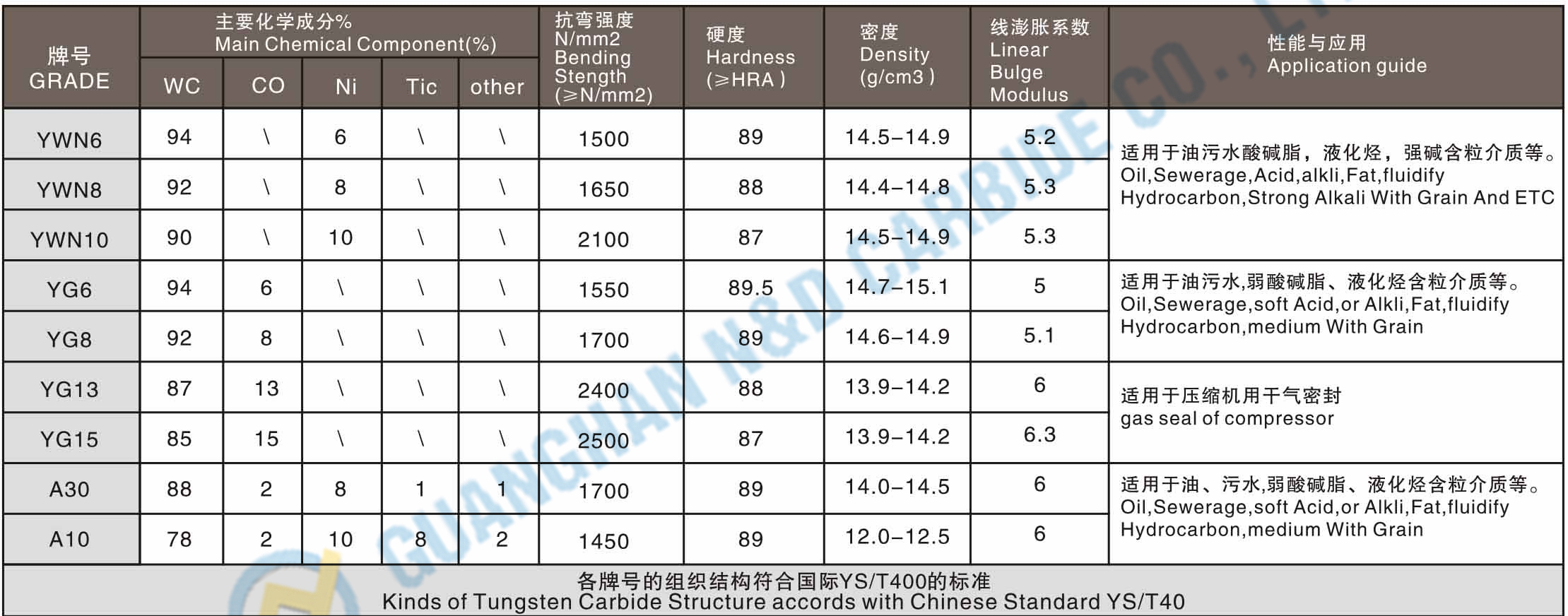

Tungsten carbide bush sleeve shows high hardness and transverse rupture strength, and it has superior performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

Tungsten carbide bushing are mainly used for stamping and stretching. It has the characteristics of wear resistance and impact resistance. It is the supporting parts used in the mechanical parts, in order to achieve sealing, wear protection and other functions.In the field of valve applications, the tungsten carbide bushing is in the bonnet and is the corrosion-resistant materials for sealing.In the field of valve applications, the tungsten carbide bushing is in the bonnet and is the corrosion-resistant materials for sealing.

The tungsten carbide bush sleeve will be used mainly for rotating support, aligning, anti-thrust and seal of the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverse working conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such as slide bearing sleeve, motor axle sleeve and seal axle sleeve.

The main function of the cemented tungsten carbide bush sleeve which is a kind of tungsten carbide part, is that it can be used as the protection part of the equipment. In the process of service, tungsten carbide bushing can effectively reduce the wear between the bearing and the equipment.

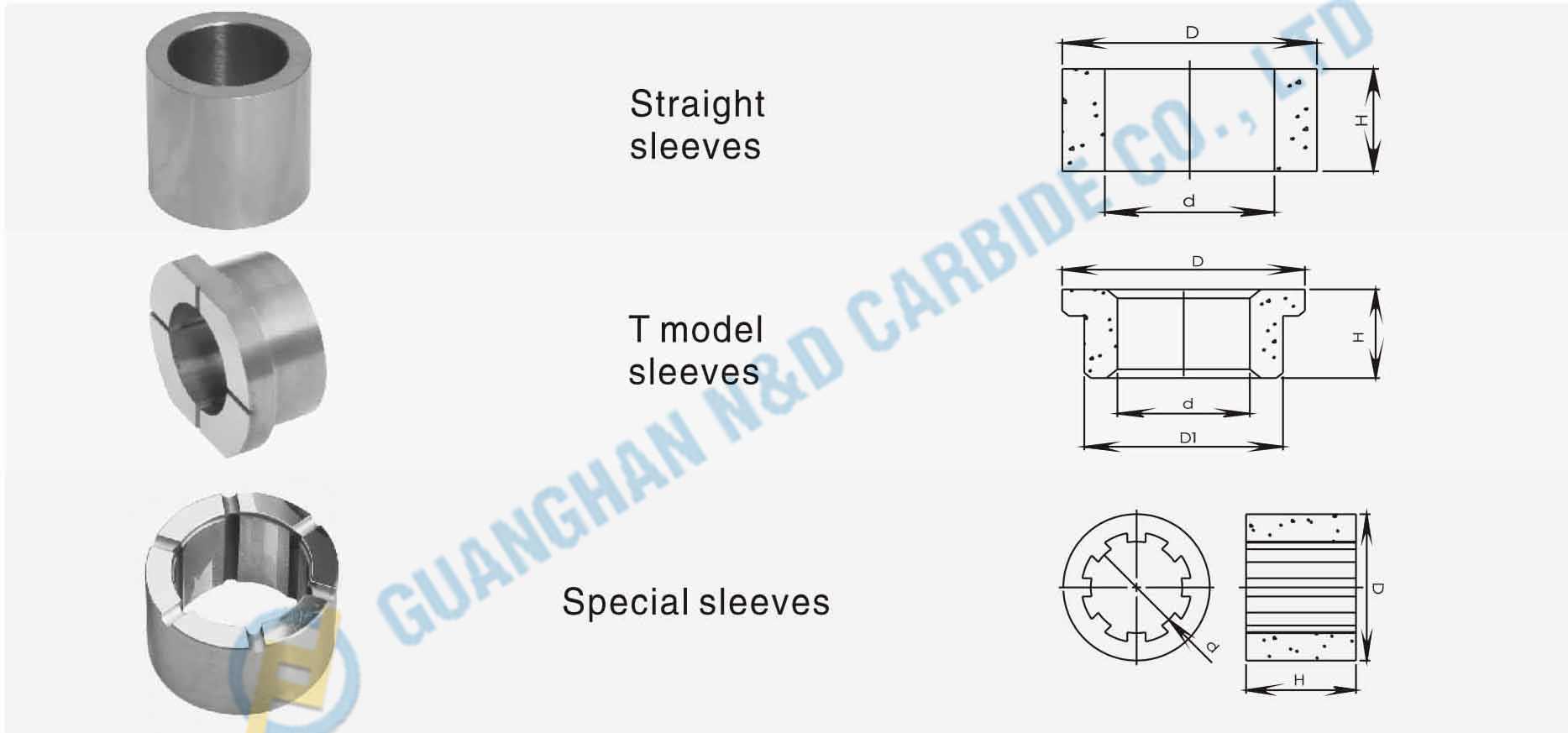

Tungsten Carbide Bushes/sleeves are mainly used as Jig Bushes, Guide Bushes, Flux Coating, Shot Blasting & many other places as a wear resistance part in various industries. We supply Plain as well as Step Bushes with different sizes & different shapes as per your requirements.

There is a big choice of sizes and types of the tungsten carbide bush sleeve, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for China Wholesale Oem Odm Custom Tungsten Carbide Bearing Sleeve Made In China Factories – Custom Carbide Bush and Sleeve – N&D, The product will supply to all over the world, such as: Greece, Finland, Singapore, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

A good manufacturers, we have cooperated twice, good quality and good service attitude.