China Wholesale Tungsten Carbide Drill Bushing Manufacturers – Tungsten Carbide Shaft Sleeve for Pump – N&D

Short Description:

China Wholesale Tungsten Carbide Drill Bushing Manufacturers – Tungsten Carbide Shaft Sleeve for Pump – N&D Detail:

Tungsten carbide is an inorganic chemical compound which contains numbers of tungsten and carbon atoms. Tungsten carbide, also known as “cemented carbide”, “hard alloy” or “hardmetal”, is a kind of metallurgic material which contains tungsten carbide powder (chemical formula: WC) and other binder (cobalt, nickel. etc.).

Tungsten Carbide – Cemented tungsten carbides are derived from a high percentage of tungsten carbide particles bonded together by a ductile metal. The common binders used for bushings are nickel and cobalt. The resultant properties are dependent upon the tungsten matrix and percentage of binder (typically 6 to 15% by weight per volume).

It can be pressed and formed into customized shapes, can be grinded with precision, and can be welded with or grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended, including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc

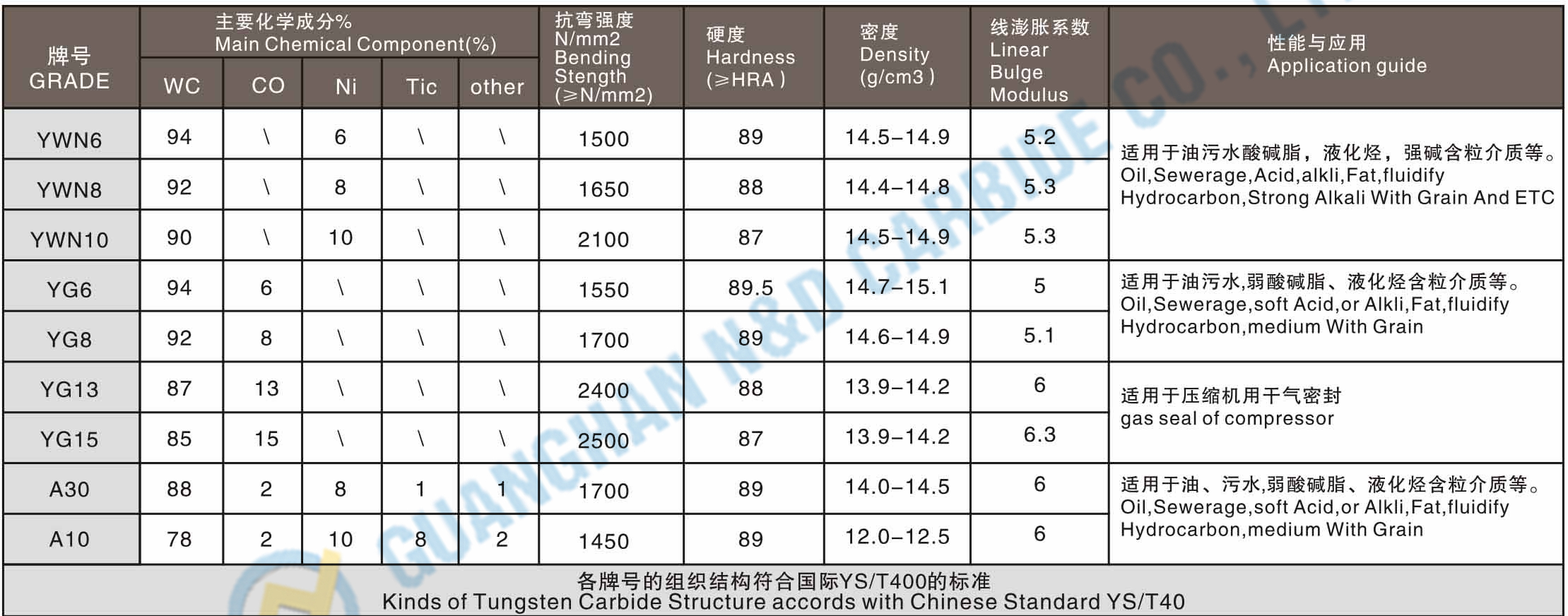

Base on different application of the users, tungsten carbide bushes are usually made of different tungsten carbide grades. The major two series of tungsten carbide grade is YG(cobalt) series and YN(Nickel) series. Generally speaking, YG series tungsten carbide bushes have higher transverse rupture strength, while YN series tungsten carbide bush resist corrosion better than the former one.

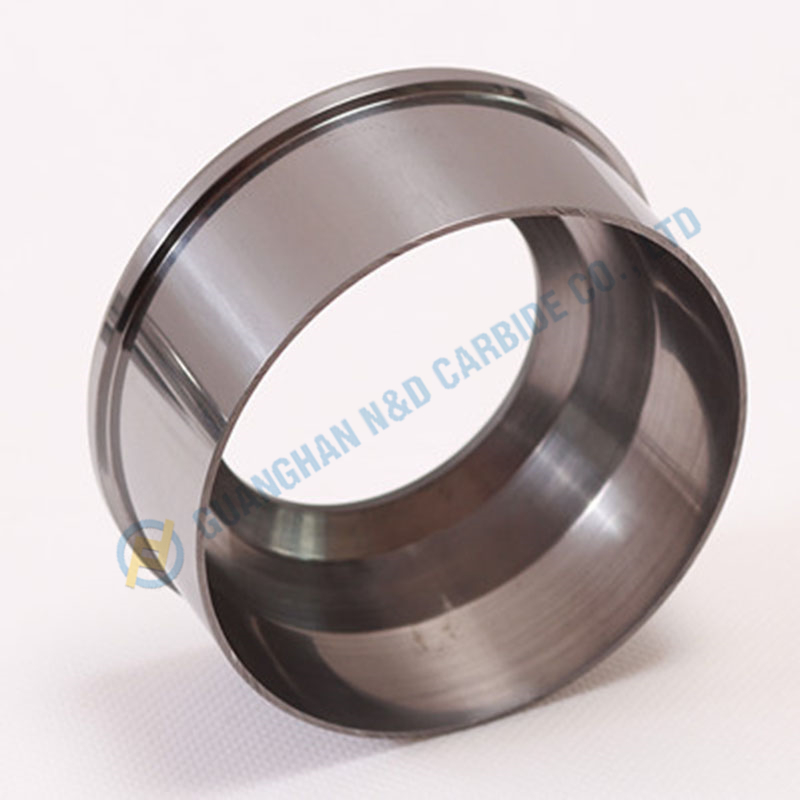

Tungsten carbide shaft sleeve shows high hardness and transverse rupture strength, and it has superior performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

The tungsten carbide shaft sleeve will be used mainly for rotating support, aligning, anti-thrust and seal of the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverse working conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such as slide bearing sleeve, motor axle sleeve and seal axle sleeve.

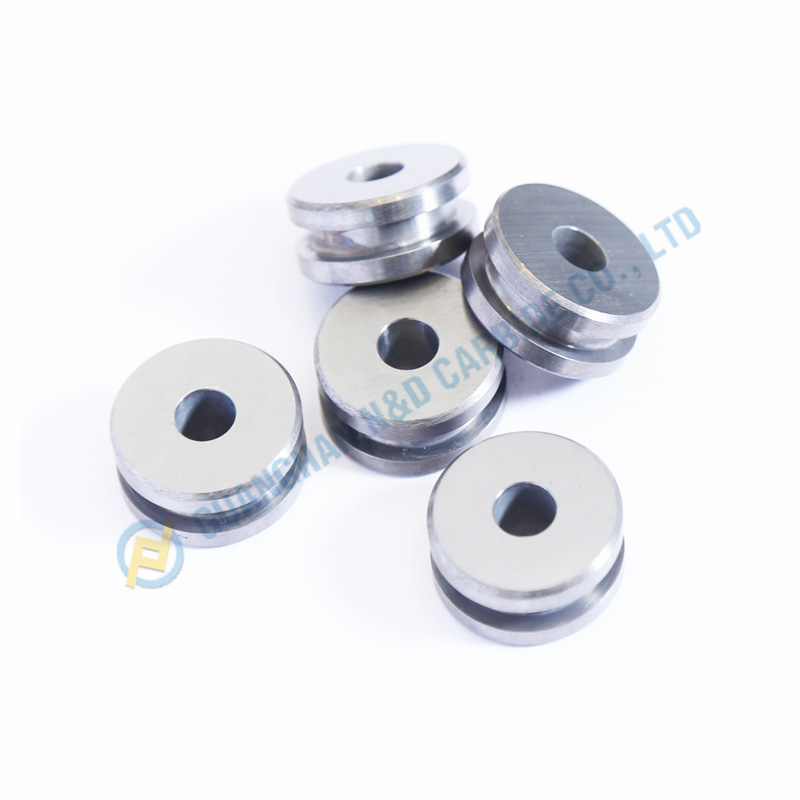

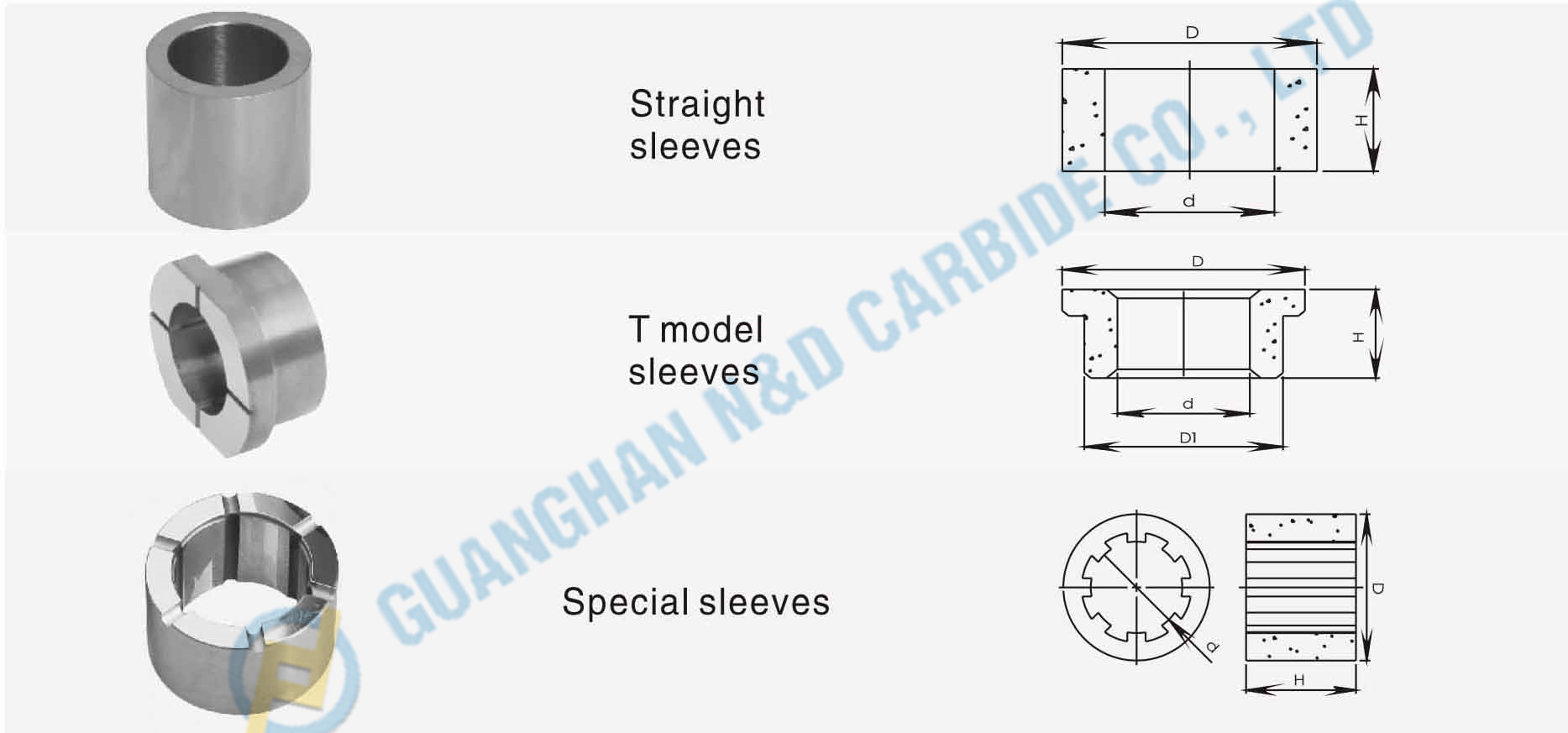

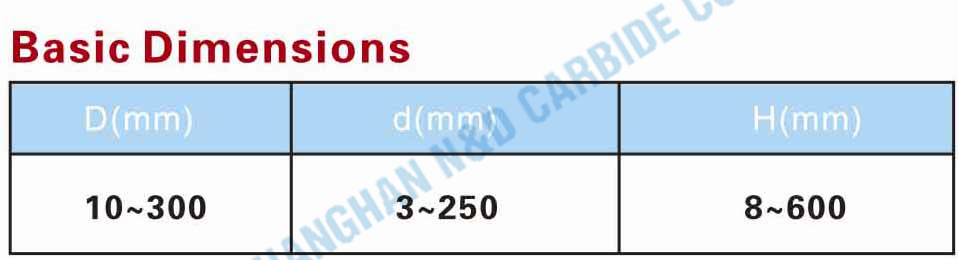

There is a big choice of sizes and types of the tungsten carbide bush sleeve, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for China Wholesale Tungsten Carbide Drill Bushing Manufacturers – Tungsten Carbide Shaft Sleeve for Pump – N&D, The product will supply to all over the world, such as: Macedonia, Monaco, Johor, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!