China Wholesale Tungsten Carbide Sealing Ring For Mechanical Sleeve Suppliers – Tungsten Carbide Flat Seal Ring for Mechanical seals – N&D

Short Description:

China Wholesale Tungsten Carbide Sealing Ring For Mechanical Sleeve Suppliers – Tungsten Carbide Flat Seal Ring for Mechanical seals – N&D Detail:

Tungsten carbide is an inorganic chemical compound which contains numbers of tungsten and carbon atoms. Tungsten carbide, also known as “cemented carbide”, “hard alloy” or “hardmetal”, is a kind of metallurgic material which contains tungsten carbide powder (chemical formula: WC) and other binder (cobalt, nickel. etc.).

It can be pressed and formed into customized shapes, can be grinded with precision, and can be welded with or grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended, including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc

Tungsten carbide is widely used in industrial machinery, wear resistant tools and anti-corrosion. Tungsten carbide is the best material to resist heat and fracture in all hard face materials.

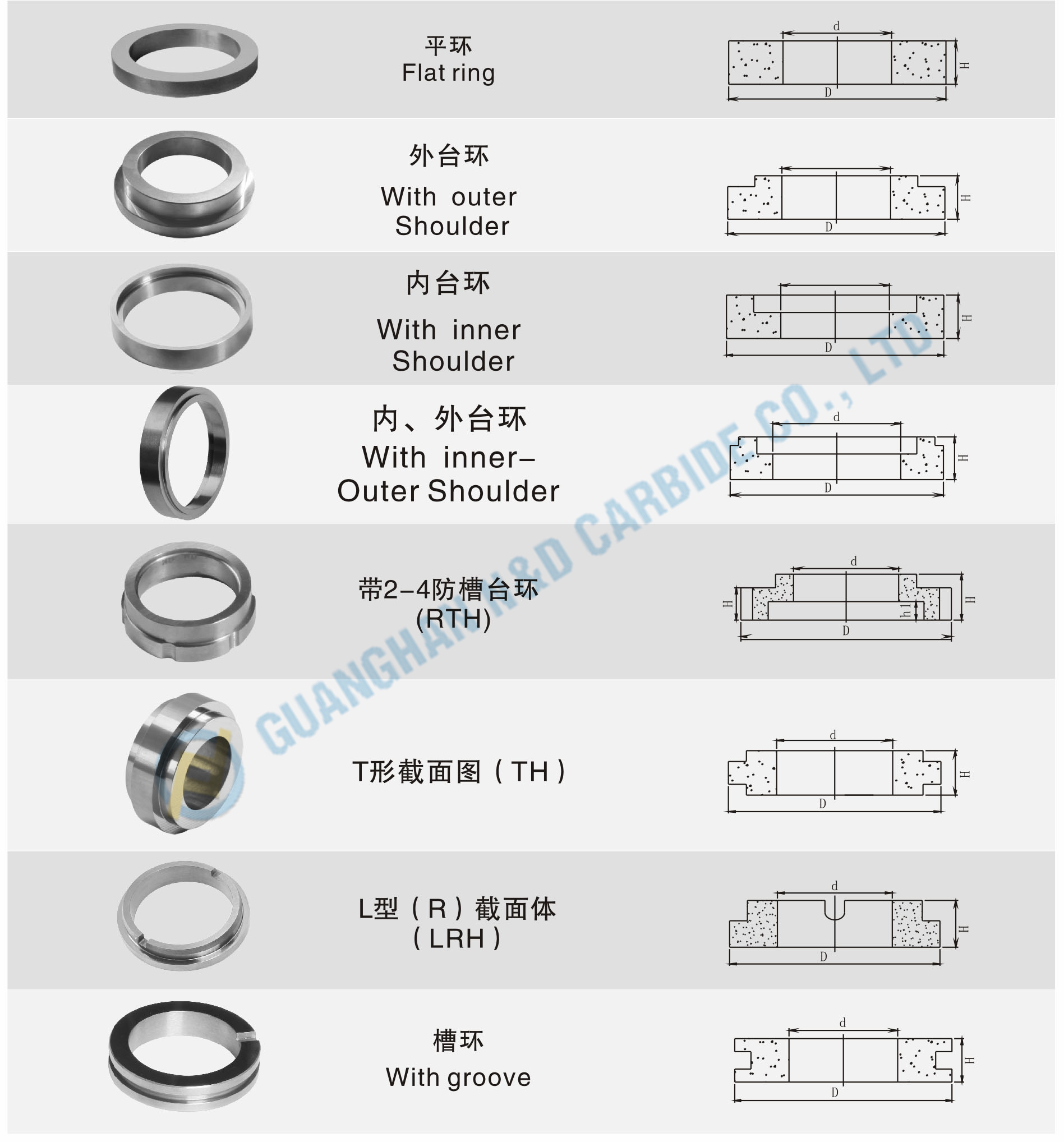

Tungsten carbide(TC) is widely used as seal faces or rings with resistant-wearing,high fractural strength,high thermal conductivity, small heat expansion co-efficient.The tungsten carbide seal-ring can be divided into both of rotating seal-ring and static seal-ring.

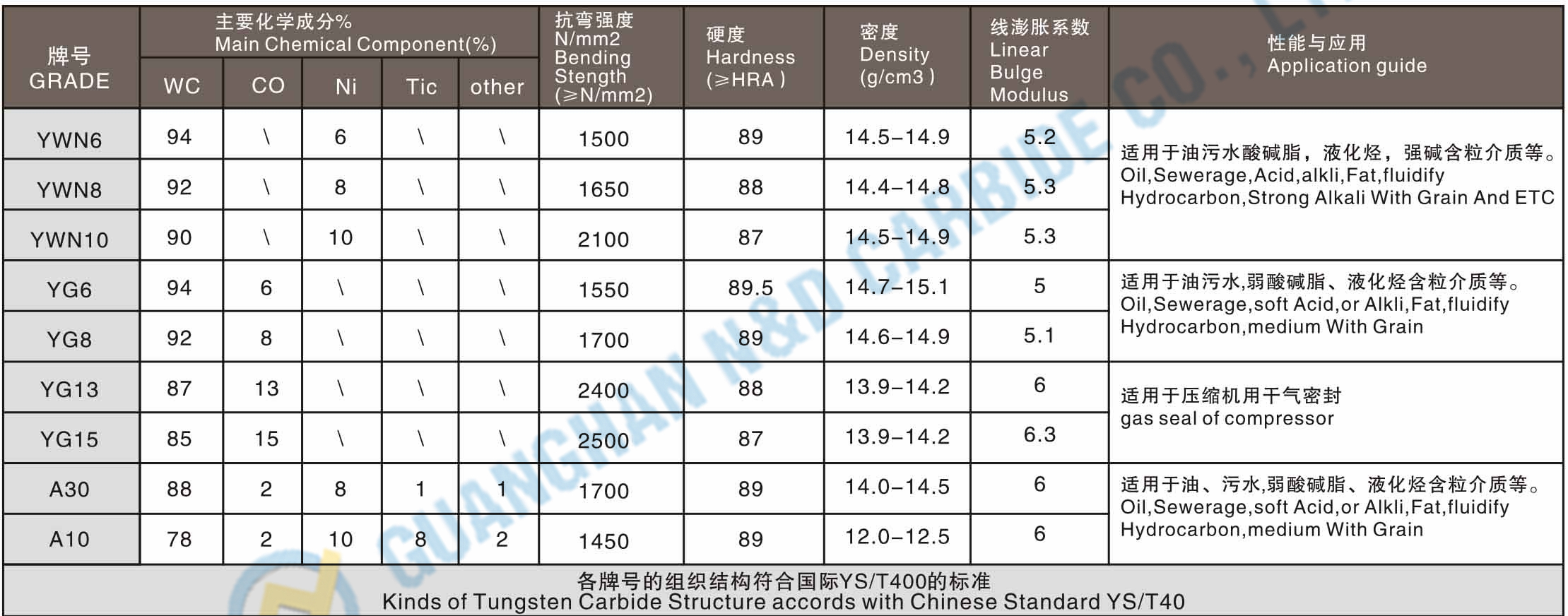

The two most common variations of tungsten carbide seal faces/ring are cobalt binder and nickel binder.

Tungsten carbide seals is provided to prevent pumped fluid from leaking out along the drive shaft. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subjected to varying external load which tend to move the faces relative to each other.

Tungsten Carbide Flat Seal Ring are widely used as seal faces in mechanical seals for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the rotating and static ring a liquid or gas seal.

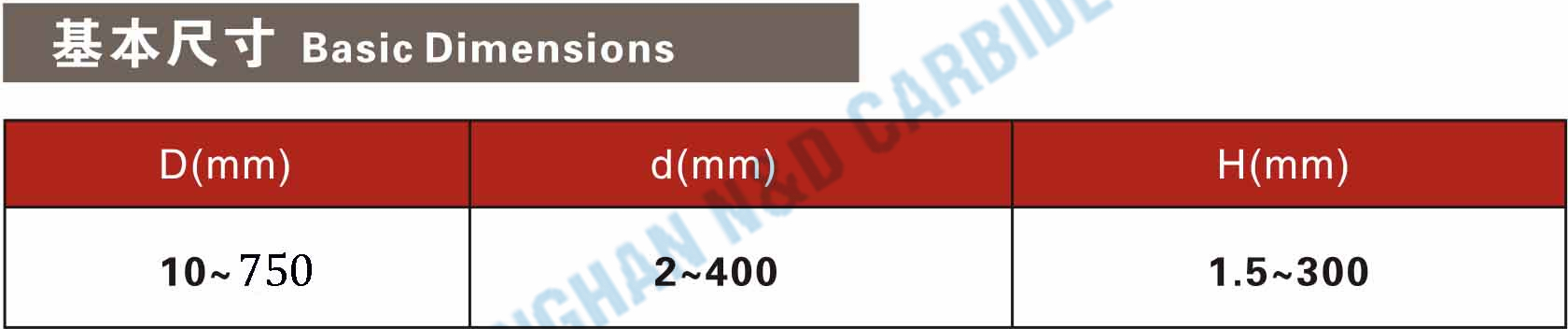

There is a big choice of sizes and types of the tungsten carbide flat seal ring, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

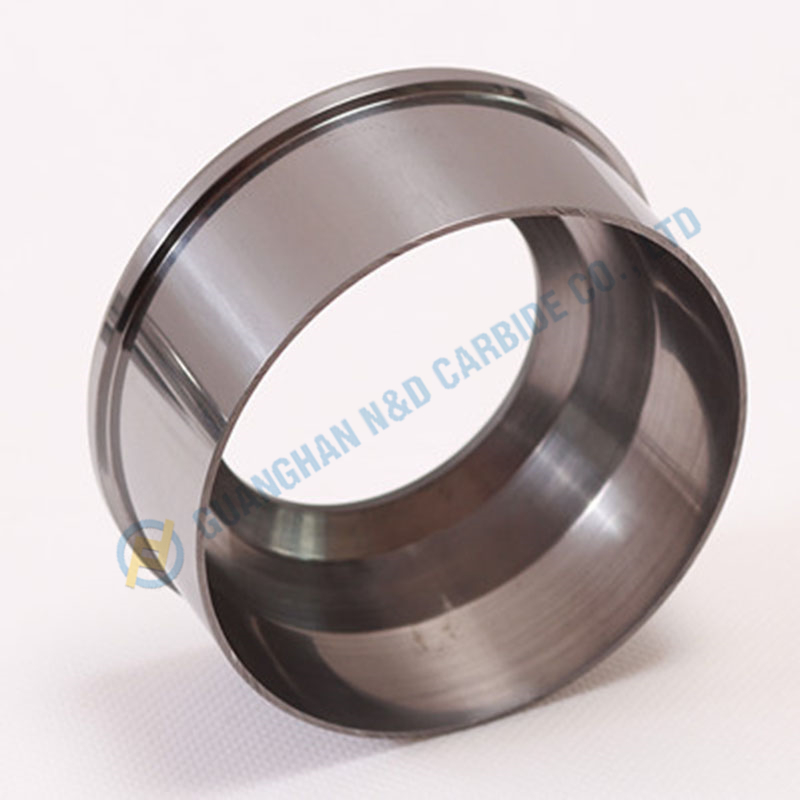

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of China Wholesale Tungsten Carbide Sealing Ring For Mechanical Sleeve Suppliers – Tungsten Carbide Flat Seal Ring for Mechanical seals – N&D, The product will supply to all over the world, such as: Belize, Toronto, Latvia, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.