Tungsten Carbide Nozzles

Short Description:

* Tungsten Carbide,cobalt binder

* Sinter-HIP Furnaces

* CNC Machining

* Erosive wear

* Customized service

The tungsten carbide nozzles will be used mainly to PDC drill bits and cone roller bits for flushing, cooling and lubricating drill bit tips and cleaning stone chips in the well bottom with drilling liquid in the working conditions of high pressure, vibration, sand and slurry impacting during oil and natural gas prospecting.

Tungsten carbide sandblasting nozzles are manufactured from hot pressing with straight bore and venturi bore type. Due to its hardness, low density and excellent wear and anti-corrosion, Tungsten carbide sandblasting nozzle has been widely used in sandblasting and shot peening equipment, offering a long life with optimum air and abrasive use.

Tungsten carbide spray nozzle of oil field have a variety of specifications, processed and made with high quality raw material. It has the characteristics of high temperature resistance, corrosion resistance, abrasion resistance, high precision and so on.

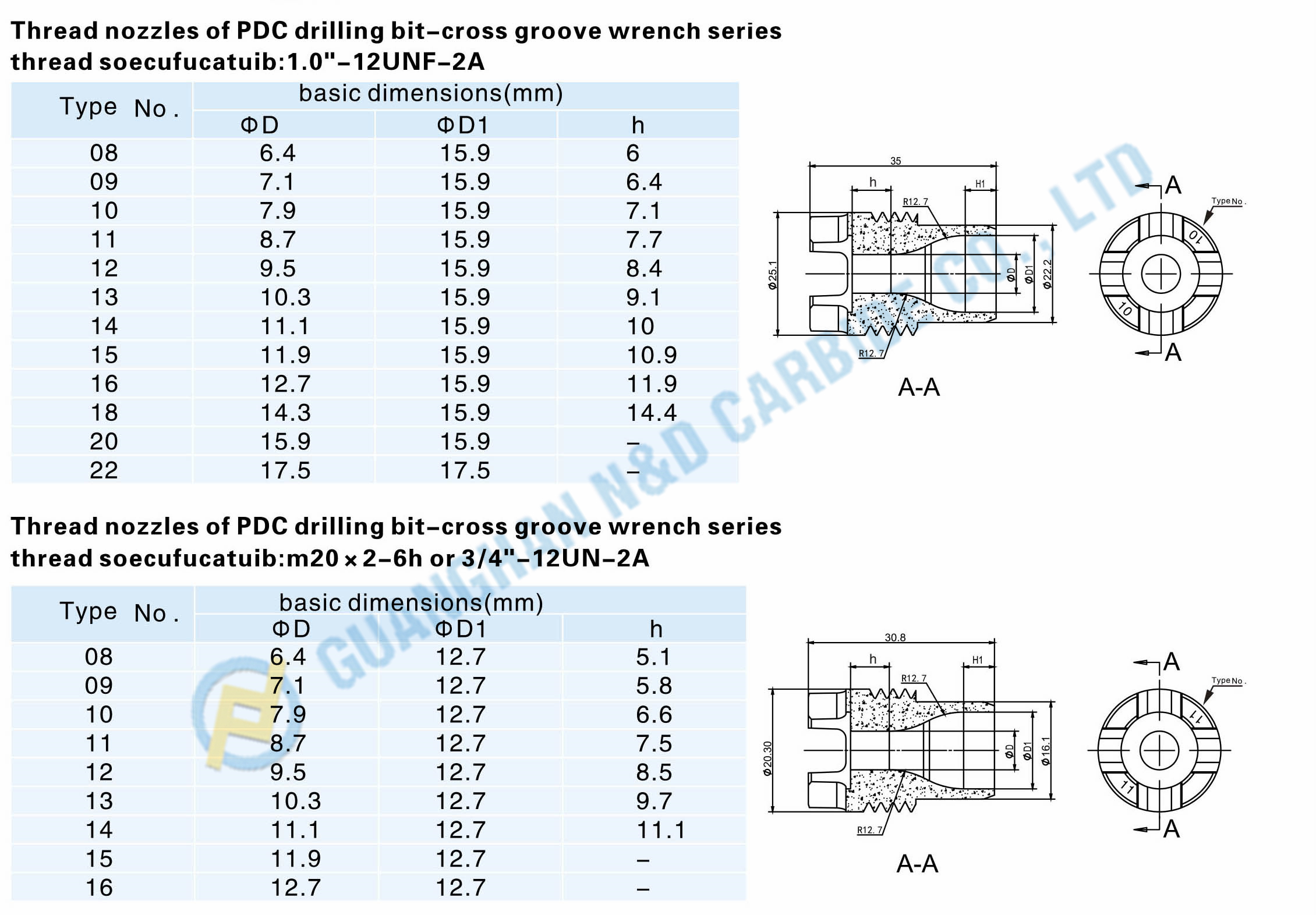

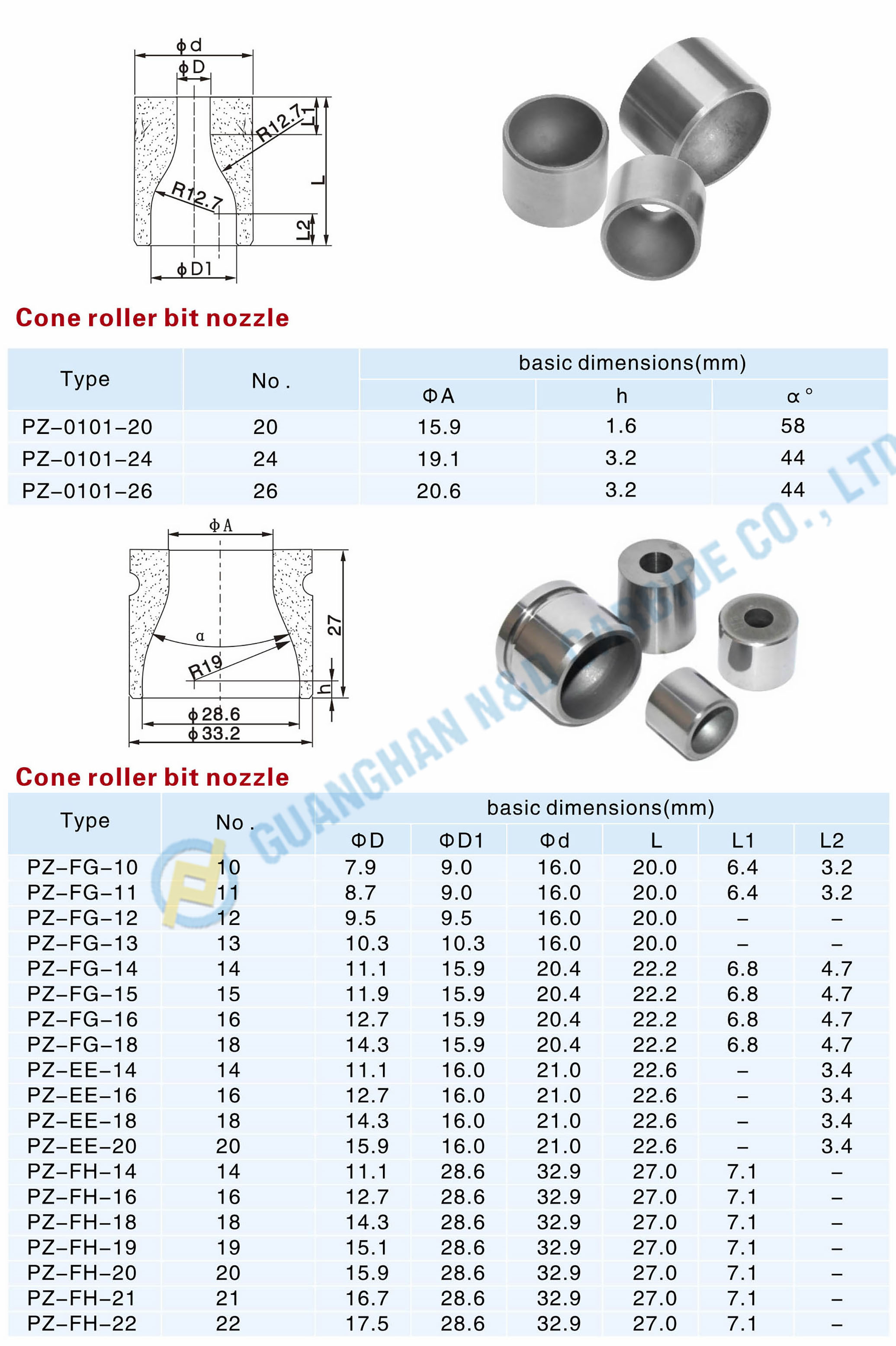

Tungsten carbide nozzle of oil field drill bit parts are available in these styles and sizes:

plum blossom type thread nozzles

internal hexagonal thread nozzles

outer hexagonal thread nozzles

cross groove thread nozzles

Y type(three grooves) thread nozzles

gear wheel drill bit nozzles and press fracturing nozzles.

For the varied requirements of our clients, we are engaged in manufacturing, supplying, exporting and trading a wide range of Tungsten Carbide Nozzles. These products are extremely rugged in state and ensure longer functional life. All these products are easy to install and needs low maintenance. These products are available in different sizes and specifications.

The products have good wear and impact resistance. The thread can be made of solid carbide or used brazing and setting technology.

Guanghan ND Carbide produces a wide variety of wear-resistant and corrosion-resistant tungsten carbide

components.

*Mechanical seal rings

*Bushings, Sleeves

*Tungsten Carbide Nozzles

*API Ball and Seat

*Choke Stem,Seat, Cages, Disk, Flow Trim..

*Tungsten Carbide Burs/ Rods/Plates/Strips

*Other custom tungsten carbide wear parts

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

We offer a full range of carbide grades in both cobalt and nickel binders.

We handle all processes in house following our customers' drawings and material specification. Even if you don't see

it list here, if you have the ideas we will produce.

Q: Are you trading company or manufacturer ?

A: We are manufacturer of tungsten carbide since 2004. We can supply 20 tons tungsten carbide product per

month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generallyit will take 7 to 25 days after order confirm.The specific delivery time depends on the specific product

and the quantity you needed.

Q: Do you provide samples? is it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers' cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test and inspection on our cemented carbide products before delivery.

1. FACTORY PRICE;

2.Focus carbide products manufacturing for 17 years;

3.lSO and AP| certified manufacturer;

4.Customized service;

5. Fine quality and fast delivery;

6. HlP furnace sintering;

7. CNC machining;

8.Supplier of Fortune 500 company.