Tungsten Carbide Wear Rings for Oil and Gas Industry

Short Description:

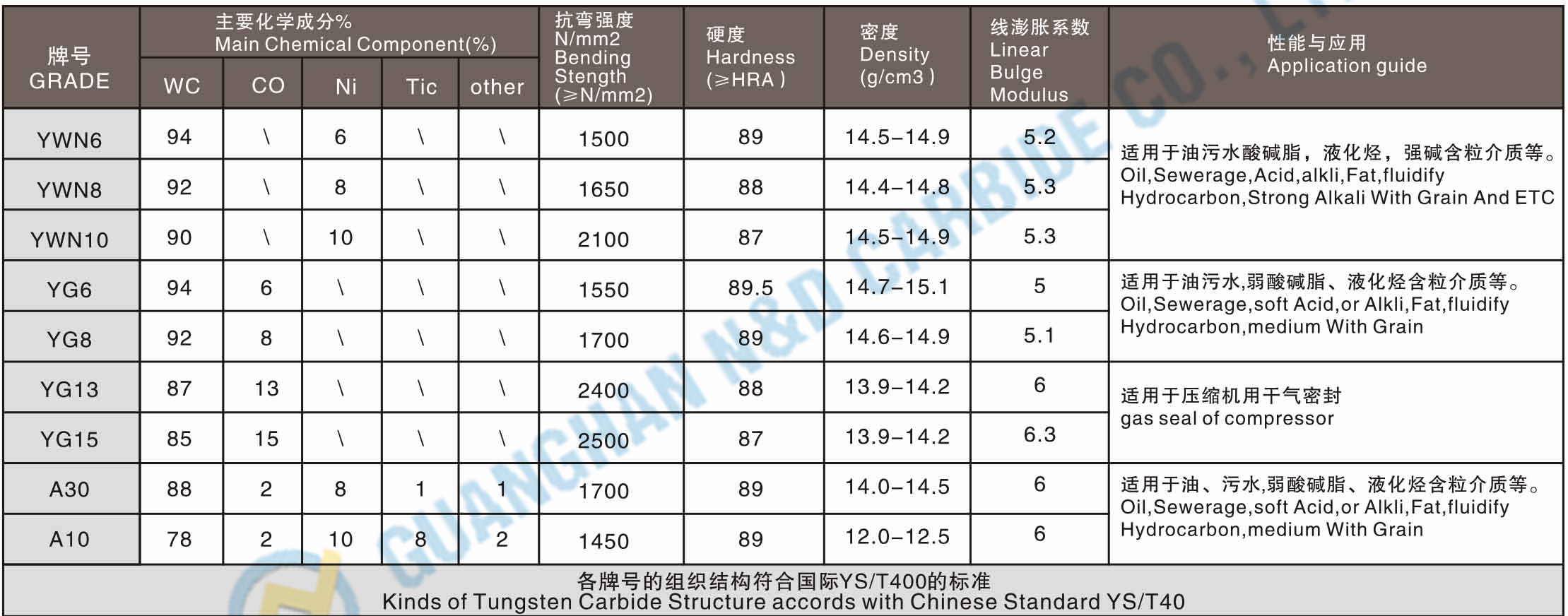

* Tungsten Carbide, Nickel/Cobalt Binder

* Sinter-HIP Furnaces

* CNC Machining

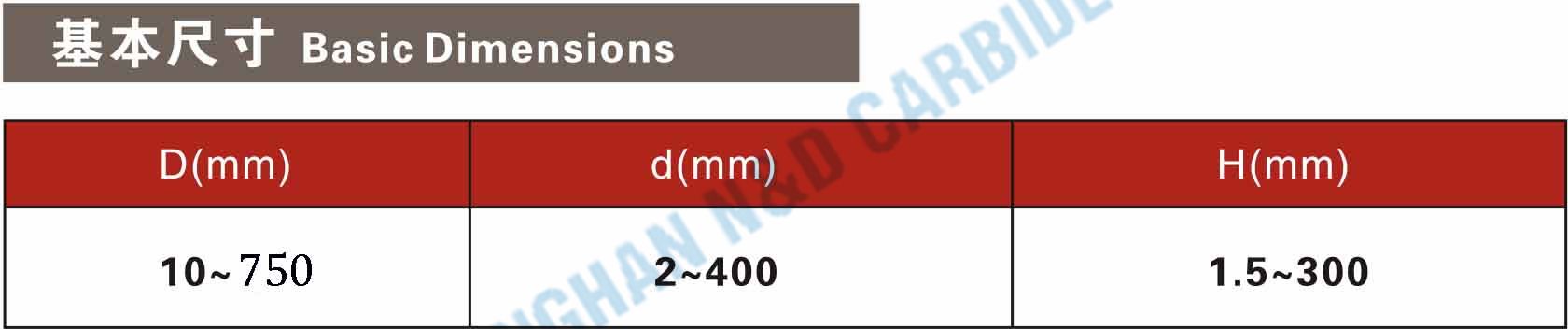

* Outer Diameter: 10-750mm

* Sintered, finished standard, and mirror lapping ;

* Additional sizes,tolerances, grades and quantities are available upon request.

The tungsten carbide wear ring is engineered for unparalleled durability in high-pressure, high-temperature, and corrosive environments. As a leader in advanced material solutions, we deliver precision-engineered seal rings that redefine performance in industrial applications.

Tungsten Carbide wear rings are widely used as seal faces in mechanical seals for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the rotating and static ring a liquid or gas seal.

Application Scenarios

- Oil & Gas: Drill stem equipment, downhole tools, and pipeline seals.

- Chemical Processing: Pumps, reactors, and valves handling aggressive fluids.

- Industrial Machinery: Compressors, turbines, and hydraulic systems.

- Marine: Subsea equipment and saltwater-resistant components.

There is a big choice of sizes and types of the tungsten carbide wear ring, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

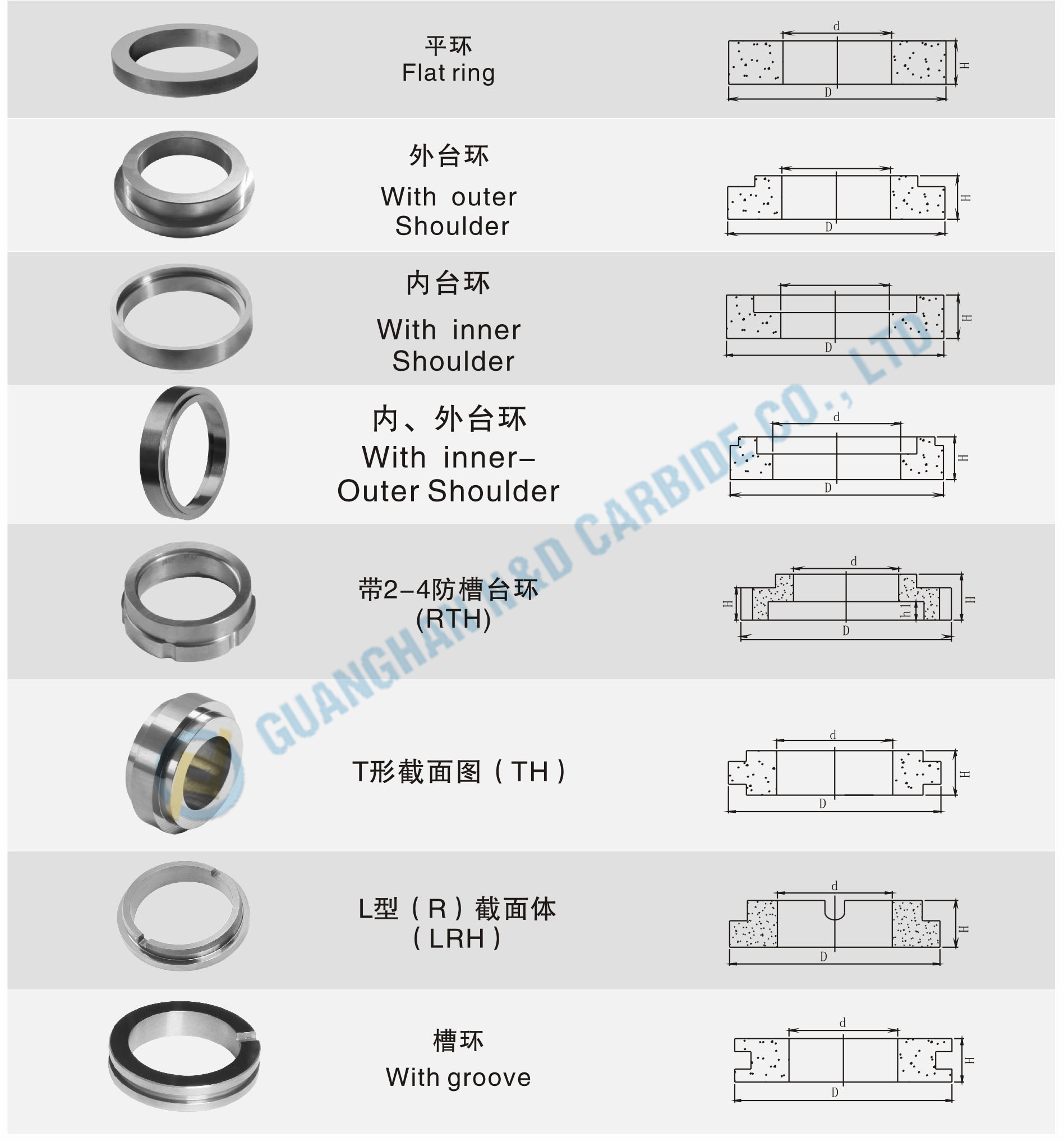

Tungsten carbide wear rings are designed in various shapes to adapt to different application equipment.

For your convenience, here are some common TC ring types:

Unmatched Wear Resistance

The tungsten carbide wear ring surpasses steel and ceramics in abrasive environments, ensuring minimal material loss and prolonged service life. Its extreme hardness (Mohs 9-9.5) makes it ideal for high-friction scenarios.

Corrosion Protection

Designed for chemical processing and marine applications, the tungsten carbide wear ring resists aggressive fluids and saltwater, preventing degradation and leakage risks.

Thermal Stability

Maintains structural integrity up to 500°C, keeping the tungsten carbide wear ring rigid and deformation-free under high-temperature operations.

Extended Lifespan

Reduces maintenance downtime by 50%+ compared to conventional seals, cutting operational costs and boosting efficiency in industries like oil & gas and mining.

Customization

Tailored geometries and surface finishes optimize the tungsten carbide wear ring for specific needs, from precision machining to high-pressure fluid handling.

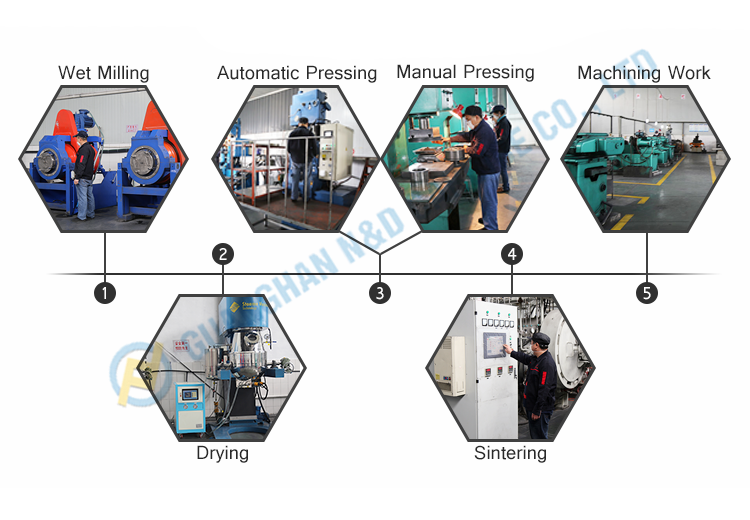

- Material Preparation: High-purity tungsten carbide powder is blended with cobalt binder for optimal hardness and toughness.

- Pressing & Sintering: High-pressure compaction followed by controlled sintering ensures minimal porosity and superior density.

- Precision Machining: Computer-controlled grinding achieves micron-level accuracy for perfect sealing surfaces.

- Surface Treatment: Optional coatings enhance corrosion resistance and reduce friction.

Guanghan ND Carbide produces a wide variety of wear-resistant and corrosion-resistant tungsten carbide

components.

*Mechanical seal rings

*Bushings, Sleeves

*Tungsten Carbide Nozzles

*AP| Ball and Seat

*Choke Stem,Seat, Cages, Disk, Flow Trim..

*Tungsten Carbide Burs/ Rods/Plates/Strips

*Other custom tungsten carbide wear parts

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

We offer a full range of carbide grades in both cobalt and nickel binders.

We handle all processes in house following our customers' drawings and material specification. Even if you don't see

it list here, if you have the ideas we will produce.

Q: Are you trading company or manufacturer ?

A: We are manufacturer of tungsten carbide since 2004. We can supply 20 tons tungsten carbide product permonth. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generallyit will take 7 to 25 days after order confirm.The specific delivery time depends on the specific product and the quantity you needed.

Q: Do you provide samples? is it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers' cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test and inspection on our cemented carbide products before delivery.

1. FACTORY PRICE;

2.Focus carbide products manufacturing for 17 years;

3.lSO and AP| certified manufacturer;

4.Customized service;

5. Fine quality and fast delivery;

6. HlP furnace sintering;

7. CNC machining;

8.Supplier of Fortune 500 company;